Treating wastewater comes with real challenges. Traditional systems can be bulky, inefficient, and a headache to maintain. That’s why today’s advanced solutions are such game-changers; they offer powerful treatment options without the usual complications.

The Waterloo Biofilter® System stands out as one of these revolutionary solutions, and Clear Water Industries has become a leading provider of these remarkable systems throughout Massachusetts. We’ve picked this product for a reason — we only partner with quality manufacturers because you deserve nothing less. You can count on the Waterloo Biofilter System for efficient wastewater management that just works, plain and simple.

The Waterloo Biofilter system is a compact, reliable, low-maintenance septic system that has been fully approved in Massachusetts.

While conventional septic systems use a tile bed to treat and dispose of septic tank effluent, the Waterloo Biofilter system uses a highly efficient, patented filter medium to provide a consistent, high-level treatment, making disposal in the soil easy.

This system is especially effective for difficult sites, such as small lots, heavy clay soils, shallow or exposed bedrock, and high water tables, such as those in the New England coastal areas.

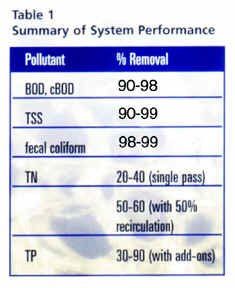

The Waterloo Biofilter® system is a single-pass aerobic biofilter designed for the biological treatment of wastewater. The patented process utilizes an absorbent synthetic filter medium designed to optimize the biological degradation of wastewater. Natural microbial action in the filter medium is enhanced by its high porosity, large available surface area, excellent airflow characteristics, and ease of microbial attachment. The filter medium has optimized flow characteristics, which allow for a high loading rate and compact size. Allowable loading rates are typically 10 times greater than sand filters or soils. The Biofilter typically removes 90-98% BOD, 90-99% TSS, 50-60% TN, and 98-99% coliform bacteria.

The septic tank treats raw sewage by fermentation (just like making beer or wine). As such, it is important not to kill the bacteria that carry on this process by using excessive disinfectants in the household.

An effluent filter on the septic outlet screens out large particles, ensuring effective treatment by the Biofilter®.

The pump chamber collects septic tank effluent, which is sprayed onto the Biofilter® on a timed basis.

The Biofilter® consists of a patented absorbent filter medium contained in patented mesh baskets, which are sized according to your daily waste use.

The Biofilter® medium houses beneficial microbes that degrade and oxidize organic pollutants, coliform bacteria, ammonium, and other contaminants in septic tank effluent.

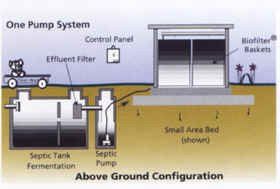

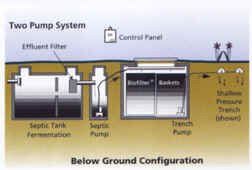

The Biofilter® unit may be placed above or below ground.

The treated effluent is disposed of in a pressure distribution disposal bed or trench.

For a normal household, the expected effluent quality is 0 to 15 mg/L BOD or cBOD (organic matter), 0 to 10 mg/L total suspended solids (TSS), 20-60% total nitrogen removal, and 98-99% fecal coliform removal.

The Table to the left summarizes the Waterloo Biolfilter® system performance.

The Waterloo Biofilter System blows traditional wastewater treatment out of the water. For starters, it uses way less energy than conventional systems, which immediately means money back in your pocket month after month.

Another significant advantage is space. These systems take up about half the footprint of traditional options, which means more usable space for your property. The absorbent foam filtration media sets this system apart as well, as it tackles wastewater treatment without needing chemicals or additives that might harm the environment.

Maintenance? Much simpler. You’ll deal with fewer mechanical parts that can break down, and the self-cleaning design means less hands-on attention. The system handles flow variations remarkably well, so those usage spikes won’t throw it off balance like they would with older technology.

The Waterloo system requires less maintenance than traditional setups, as you usually only need annual pumpouts. Maintenance visits may involve checking the pump, cleaning filters, and making sure everything is running properly. Between these visits, you simply need to glance at the system indicator lights to check that they’re green.

The Waterloo system was practically made for tough New England winters. It keeps working smoothly even when temperatures drop below freezing and can even maintain treatment levels in temperatures down to -50°C without the need to heat raw sewage. The filter media doesn’t freeze as liquid systems might, and the aerobic bacteria continue breaking down waste even in cold conditions. The system’s components are insulated, and the biological processes efficiently help maintain performance. We’ve installed these systems throughout Massachusetts and watched them perform consistently year-round.

The Waterloo Biofilter® shines because it handles the peaks and valleys of household water usage better than most systems. When everyone takes showers before work, does laundry on weekends, or hosts holiday gatherings, the system adapts without missing a beat. Property owners love the quiet operation — no loud pumps or equipment disrupting your peace and quiet. Many also appreciate the system’s small footprint, which preserves yard space for gardens, play areas, or patios. Plus, the lower power consumption translates directly to lower bills month after month.

Clear Water Industries proudly provides the Waterloo Biofilter® System, along with other products like Orenco Onsite Wastewater Products. We also offer effective and timely septic system maintenance.

The Waterloo Biofilter® System gives you reliable, eco-friendly wastewater treatment that truly works. You’ll save on energy costs, use less space, and deal with fewer headaches than traditional systems. Plus, you’ll be ahead of the curve on Massachusetts regulations! Give us a call today to learn more about the Waterloo Biofilter® System.